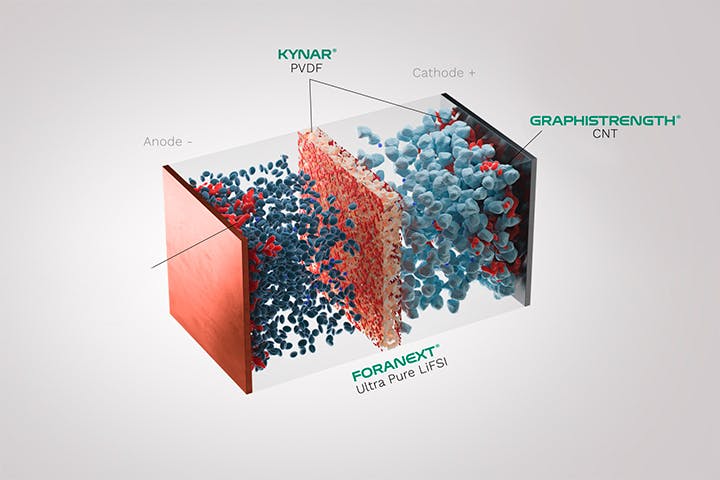

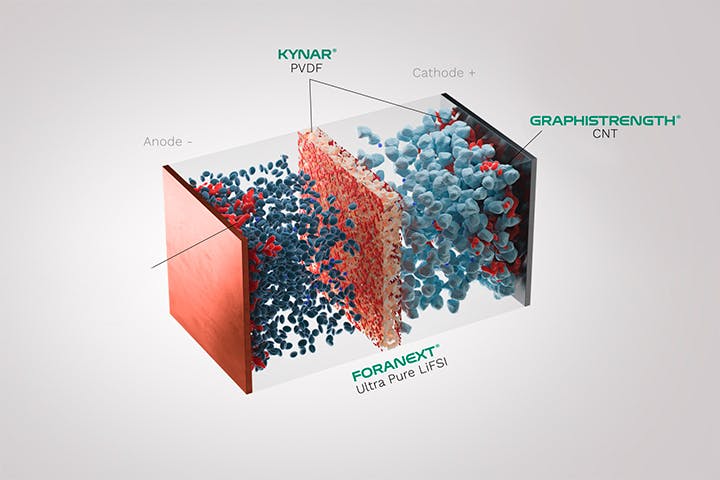

1 Electrodes and separator film:

SUSTAINABLE GROWTH FOR KYNAR® PVDF

A critical material in Li‑ion batteries, PVDF (polyvinylidene fluoride) performs essential functions to protect the separator film (between the anode and cathode), where it provides safety and increases the life of batteries. It also binds active particles to the cathode to improve energy efficiency in the cells. Arkema is now one of the main producers of PVDF under the Kynar® brand, for which it has been developing specific grades for 25 years. Arkema is achieving long‑term, double‑digit annual growth in this market, and is gaining more momentum by further strengthening its presence in both production and R&D across the three main regions responsible for the future of electric mobility: Europe, North America and Asia.

The Group has therefore decided to increase its production capacity of Kynar® PVDF in China to 50% for 2022 and to achieve a 50% increase in the capacity of its factory in Pierre‑Bénite (France) by 2023.

2 Carbon nanotubes Graphistrength®:

A BIG ADVANTAGE FOR ELECTRODES

Arkema is one of the world’s few producers of carbon nanotubes. Added in small quantities to the cathode, they significantly improve electronic conductivity by helping the flow of electrons to the anode, thus reducing battery charge time.

3 Electrolyte salts Foranext®:

A STATE‑OF‑THE‑ART SOLUTION FOR HIGH‑VOLTAGE BATTERIES

Higher battery voltage is a significant market trend that increases the requirements for the electrolyte salts used in each cell. Arkema anticipated this need by investing for several years in the development of an ultra‑pure LiFSI electrolyte salt, which offers higher conductivity than current solutions, enabling reliable performance in cold weather and reduced charging time. Arkema has also developed a LiTDI additive used in electrolyte formulations to increase their durability. This breakthrough technology will be marketed in 2023.

4 Innovative binders FOR THE ANODES OF TOMORROW

The next generation of Li‑ion batteries will incorporate a graphite/silicon anode for which current binders have limited performance. For this emerging technology, which could take the lead by 2030, Arkema is developing specific grades of binders, based on newly patented resins, thus creating significant potential for growth.