A true agent for charging electric vehicle batteries (see p.18), PVDF is also a key component of fuel cells.

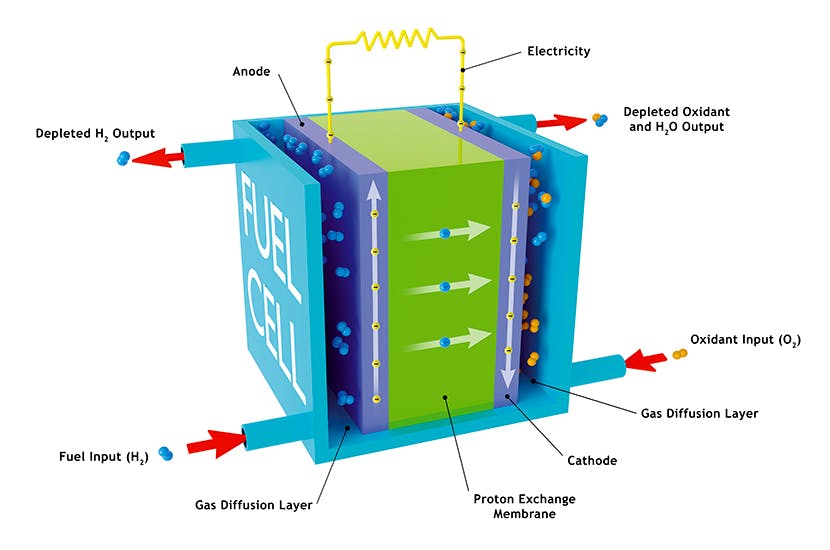

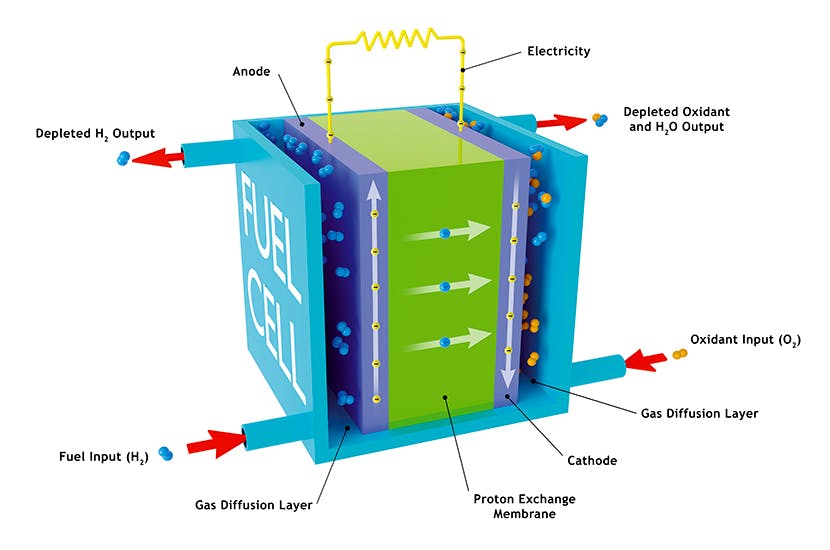

Due to its high electrochemical stability, it plays an essential role as a binder in the formulation of the graphite double pole plates that serve as a current collector, ensuring the cooling and transportation of gases. Arkema already sells significant quantities of its Kynar® PVDF for this application. The Group is also developing functionalized Kynar® grades with properties including advanced proton conduction, temperature stability and chemical degradation resistance. These will boost the performance of the exchange membranes, which conduct protons within the battery, within the next four to five years.

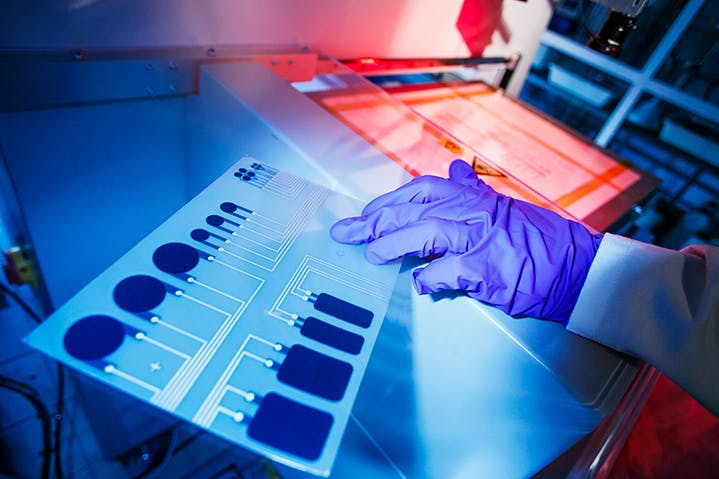

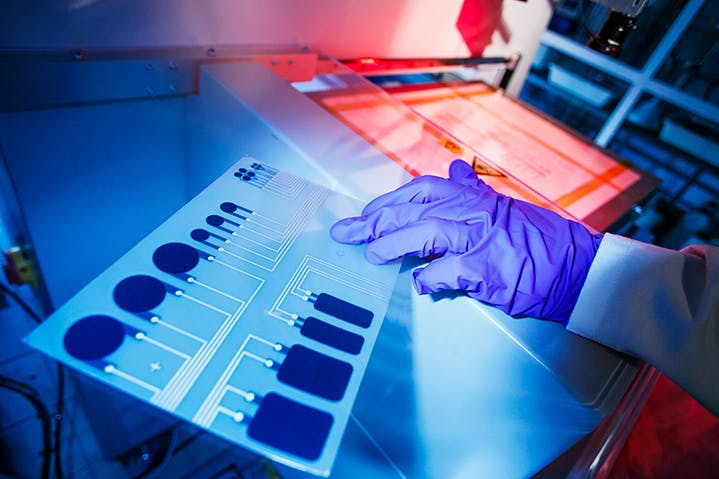

The fluorinated electroactive polymers of the Piezotech® range, sensitive to shocks, deformations and acoustic vibrations, open up prospects for innovation with high added value for the safety of hydrogen vehicles. Used to form sensors embedded in the composite layer, they can provide a continuous monitoring function for the condition of hydrogen tanks, which also allows manufacturers to size the structure as accurately as possible with regard to safety issues, generating raw material savings. Arkema expects the first launches of this application, which is still in the R&D stage, to be within the next three to five years.

Rilsan® polyamide 11: bio‑sourced solutions for the liner and for winding

Rilsan® polyamide 11, a 100% bio‑sourced high-performance polymer, has the qualities required to form the interior liner of high‑pressure tanks. Impermeable to hydrogen, resistant to cold shocks (the tank temperature may drop to -50°C in the event of rapid depressurization), barely affected by temperature variations and easy to work with, including for large parts (tanks for trucks, for example), it is already being used by several manufacturers. Within the next two or three years, it will also offer a next‑generation solution for the production of carbon fiber composite tapes pre‑impregnated with Rilsan® fine powder, making it possible to form a tank shell that also acts as a liner by hot winding. It is an excellent choice for manufacturers as it does not need to be cured after winding and requires less carbon fiber (the main cost factor for tanks) than epoxy with the same resistance.